│ Wireharness’ Design Strategy to Minimize EMI

A sudden signal error in an operating room using a robot, unstable data from sensors in an autonomous vehicle, a momentary interruption of the aircraft navigation system. Behind all these fatal moments is a common culprit: electromagnetic interference, EMI. Hundreds or thousands of signals must be transmitted accurately and quickly through these thin lines. But the world we live in is full of electromagnetic fields.

Electromagnetic waves from motors, power supplies, wireless communication, and even other cables constantly disturb signals. EMI is a task that cannot be overlooked, especially in a field where military-level precision is directly linked to life, such as medical robots.

│ What is EMI: Invisible Noise

EMI = Electromagnetic Interference

EMI comes in two main forms, conductive and radioactive. Conductive EMI is interference carried directly through a power line or cable. AC power line motors, motors, variable frequency drives, and welding equipment are the main sources. Radioactive EMI refers to wirelessly propagated interference, including short-range interference and crosstalk inside the cable.

*Crosstalk: A phenomenon in which a signal flowing from a pair of conductors is exposed to another pair nearby

📌 We present four key strategies for minimizing EMI noise in WireHannes.

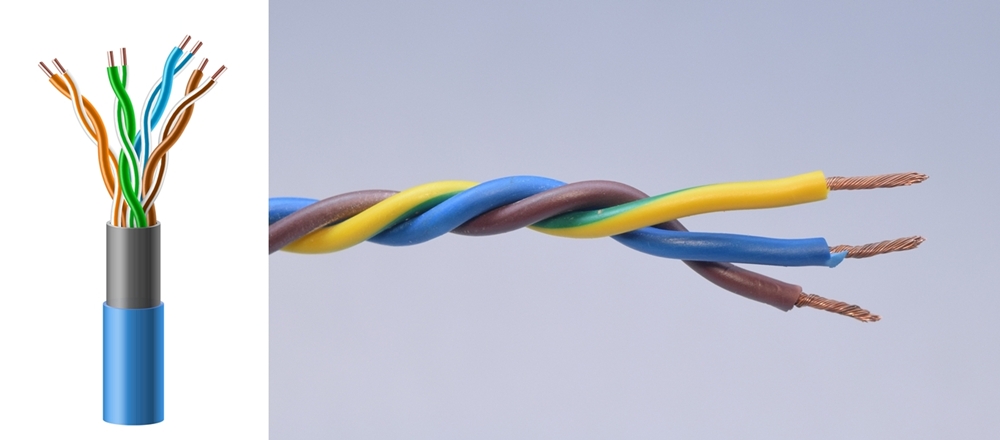

1️⃣ Twisted pair_Why the technology of 1881 is still in effect

2️⃣ Shielding_Cage locking electromagnetic field

3️⃣ Signal separation and path design

4️⃣ Designed as a safe return path for grounding_EMI current

Strategies for reducing EMI noise in Wirehannes can be summarized by breaking the interference in three stages: generation, transmission, and reception.

Below, I will explain each strategy systematically.

Source : AdobeStock

🔗 First strategy: Twisted pair_Why the 1881 technology is still in effect

Patented in 1881 by Alexander Graham Bell, the “twist pair technology” is still fundamental to EMI responses 140 years later. The reason lies in an astonishingly elegant physical principle. When two parallel lines receive currents in opposite directions, the space between them adds a magnetic field. If the line is not twisted, a non-zero magnetic field is formed around it, which induces unwanted voltages in the neighboring circuits. However, when the lines are twisted together, the magnetic field is reversed for each adjacent half twist, canceling out each other. The more twisted the magnetic field cancels out, the greater the net magnetic field over the entire length, making the voltage induced in the neighboring circuit nearly zero as well.

The actual test results were impressive. Adding the first five twists with 1m cable and no twists will reduce radiation by about 25dB. Making a total of 100 twists by twisting an additional 95 times will result in another 25dB improvement. While the effect felt can be reduced, the proper twist ratio is the most cost-effective EMI noise minimization method.

Patented in 1881 by Alexander Graham Bell, the “twist pair technology” is still fundamental to EMI responses 140 years later. The reason lies in an astonishingly elegant physical principle. When two parallel lines receive currents in opposite directions, the space between them adds a magnetic field. If the line is not twisted, a non-zero magnetic field is formed around it, which induces unwanted voltages in the neighboring circuits. However, when the lines are twisted together, the magnetic field is reversed for each adjacent half twist, canceling out each other. The more twisted the magnetic field cancels out, the greater the net magnetic field over the entire length, making the voltage induced in the neighboring circuit nearly zero as well.

The actual test results were impressive. Adding the first five twists with 1m cable and no twists will reduce radiation by about 25dB. Making a total of 100 twists by twisting an additional 95 times will result in another 25dB improvement. While the effect felt can be reduced, the proper twist ratio is the most cost-effective EMI noise minimization method.

Source : AdobeStock

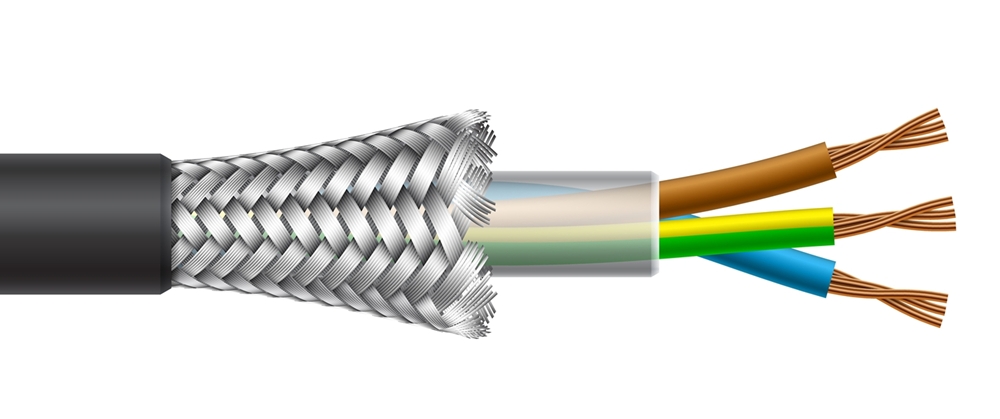

🗑️ Second strategy: shielding_cage that traps electromagnetic field

Shielding is required when the twisted pair alone is not enough. Shielding is a method of shielding or bypassing an electromagnetic field by wrapping a signal transmission conductor with a conductive material. There are several types of shielding, selected by each frequency range, flexibility, and mechanical requirements.

● Foil Shielding

It creates 100% shielding coverage by reinforcing thin metal layers with a polymer layer. It is inexpensive but has the disadvantage of slightly reducing cable flexibility.

● Braided Shielding

Made from woven wire mesh, it provides about 95% coverage due to the space between the braid. It is more conductive and mechanically durable than foil shielding.

For the strongest protection, we recommend using foil and braid together. Double protect the entire wire harness cable with braid and foil, and shield each twisted pair with foil to block external EMI and crosstalk at the same time.

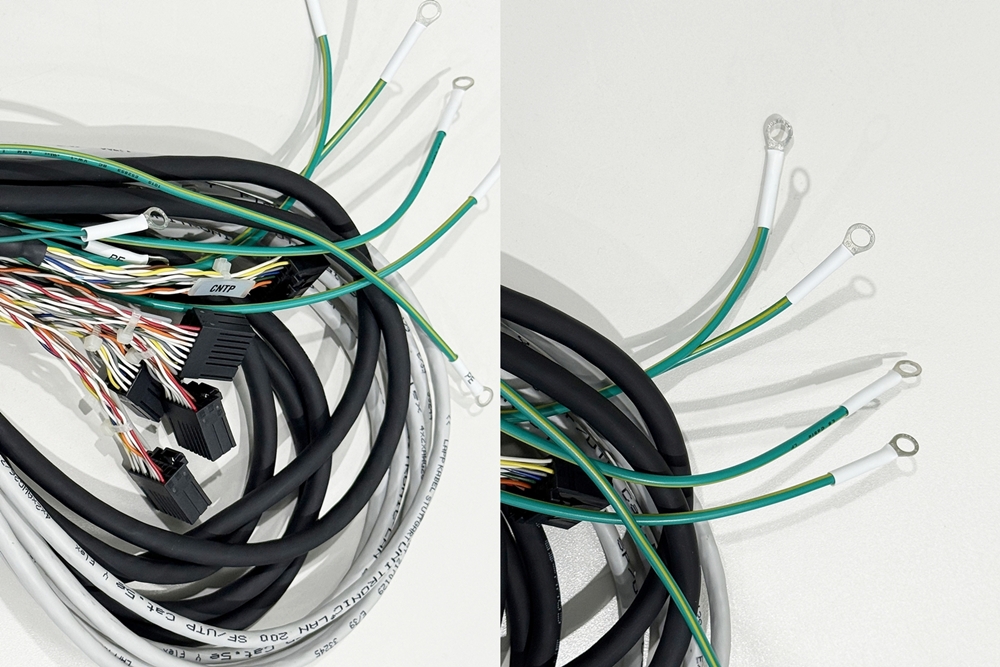

🚥 Third strategy: signal separation and path design

The physical separation method is the simplest and most effective way to minimize EMI noise. The signal cable and the power cable must be separated into separate conduits or cable trays, and if they are unavoidably crossed, they must be crossed at a 90-degree angle to maintain as much spacing as possible. In addition, no loops should be created on the cables. Because the loops behave like antennas, they can receive or emit more EMI.

⚡ Fourth strategy: Grounding

Grounding..? It refers to connecting the ground object to the ground as a ground conductor to allow current to flow to the ground.

Proper grounding is the foundation of EMI management. Drain wires on shielded cables must be grounded at one end and, where possible, select the grounding point with less electrical noise. Note that grounding at both ends can create a grounding loop, which can increase EMI. At the system level, it is ideal to use the Star Grounding method. Multiple grounding should be connected to one central point to avoid a grounding loop, and the grounding of each section should be managed by selective bonding.

One effective EMI management method is to integrate multiple techniques, not just one.

Shielded connectors inhibit electromagnetic energy at the interface, provide a clean path for high frequency current with proper grounding, and filter out signals left with common mode choke. These layered defense systems handle interference at different points in the signal path, maximizing the overall robustness of the system. When the right twist ratio, proper shielding, perfect grounding, and smart layout design are in harmony, wire harnesses become a key asset that ensures the quality of the device beyond mere bundles of wires. At BK Electronics, all strategies are integrated to provide reliable quality, from medical robots to industrial wire harnesses.

TEL.+82 031-456-2580 / MAIL. bksales00@bkec.co.kr