What is the forecast for the cable harness market in 2026?

In 2026, the transition to software-oriented cars is expected to begin in earnest, and the demand for harnesses for high-speed data transmission to connect high-performance computers or sensors is expected to surge. In addition, demand for cable assemblies for base station equipment and data centers will continue due to the expansion of 5G networks, and demand for ultra-light and high-performance harnesses will be created due to the enlightenment of the urban air mobility market such as drones and personal vehicles.

The outlook for cable harnesses is also bright for medical devices. In medical devices, cable harnesses go beyond just power sources and act like a “nervous network” that transmits patients’ biometric signals and controls surgical robots’ precise movements. In particular, the Asia-Pacific region, including Korea, is showing the fastest growth in the world as it enters an aging society and expands medical infrastructure at the same time. In 2026, the cable harness market is facing an unprecedented period of change due to technological advancement and changes in demographic structure.

Thinner, stronger and smarter, harnesses will be a key driver in advancing the era of telemedicine, robotic rehabilitation, and robotic surgery. In the end, only companies that ensure extreme precision and uncompromising safety are expected to win in this huge trend.

│Cable harness process and features

Let’s take a look at the features along with the images of the equipment mainly used in the cable harness (wire harness) process.

1) Wire Cutting & Stripping Machine

It is an equipment that accurately cuts and uninsulates wires, cutting and stripping them to specified lengths according to programmed settings. Because they are fast and accurate, there are far fewer errors in work than human hands. (More than 10 times faster than manual work) This is the first step in cable harness production to prepare wires of the correct dimensions.

It is an equipment that accurately cuts and uninsulates wires, cutting and stripping them to specified lengths according to programmed settings. Because they are fast and accurate, there are far fewer errors in work than human hands. (More than 10 times faster than manual work) This is the first step in cable harness production to prepare wires of the correct dimensions.

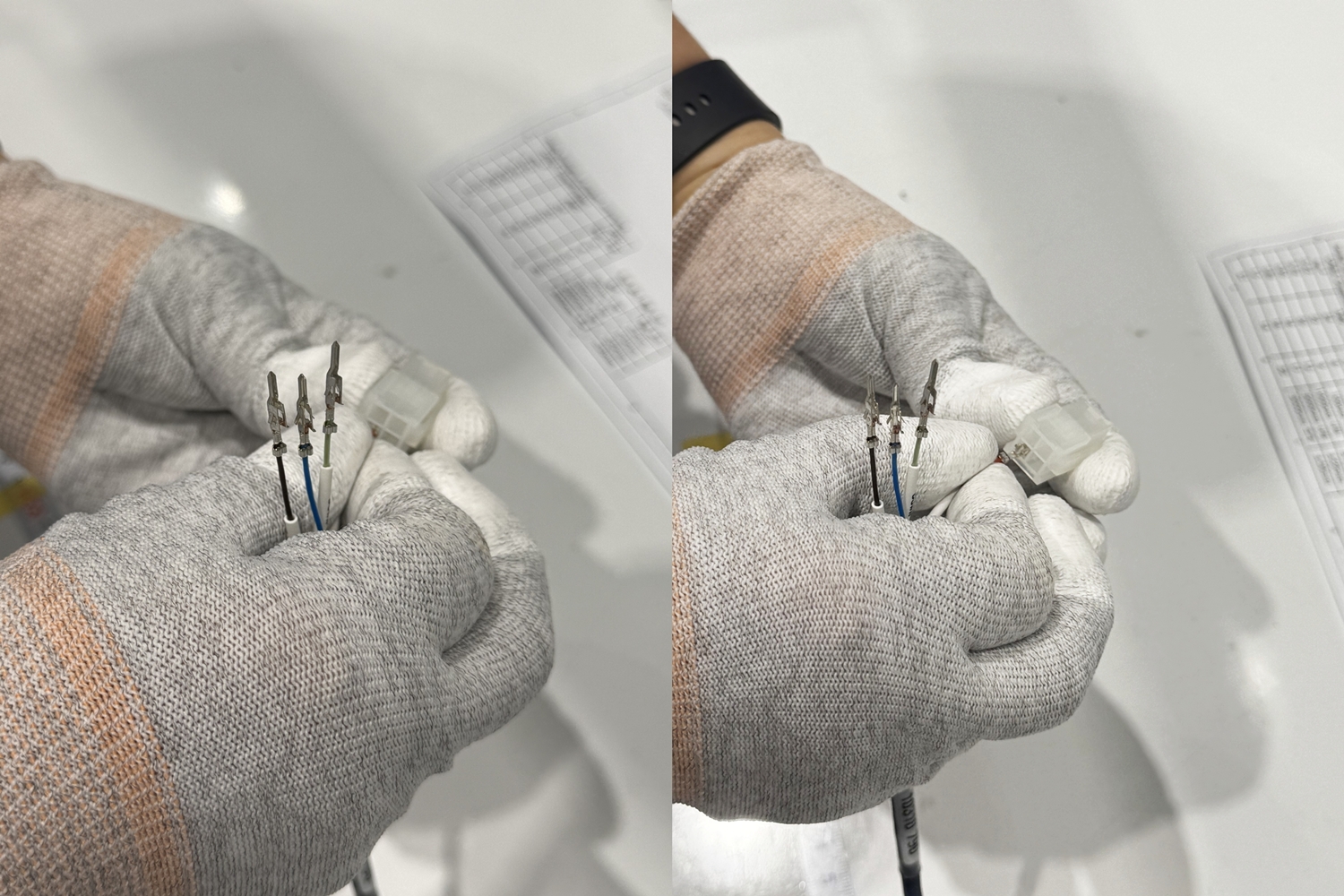

2) Crimping Machine

It is an equipment that compresses (crimps) terminals at the ends of wires. A special mold allows the terminal to be strongly bonded to the wire, and the quality of electrical and mechanical connection can be secured through this crimping operation. It prevents connection failure through fine unit adjustment and usually applies pressure of 2 tons or more to unify the wire and the terminal. The automatic or semi-automatic type can be selected according to the production volume, and the electrical reliability is important in the process of connecting the connector.

3) Assembly Workbench/Pin Board

Cable harness assembly. No additional equipment is required and pin positions are shown based on design drawings (CAD), making it easier to work with. It is a key process of assembling various wires and parts into correct positions.

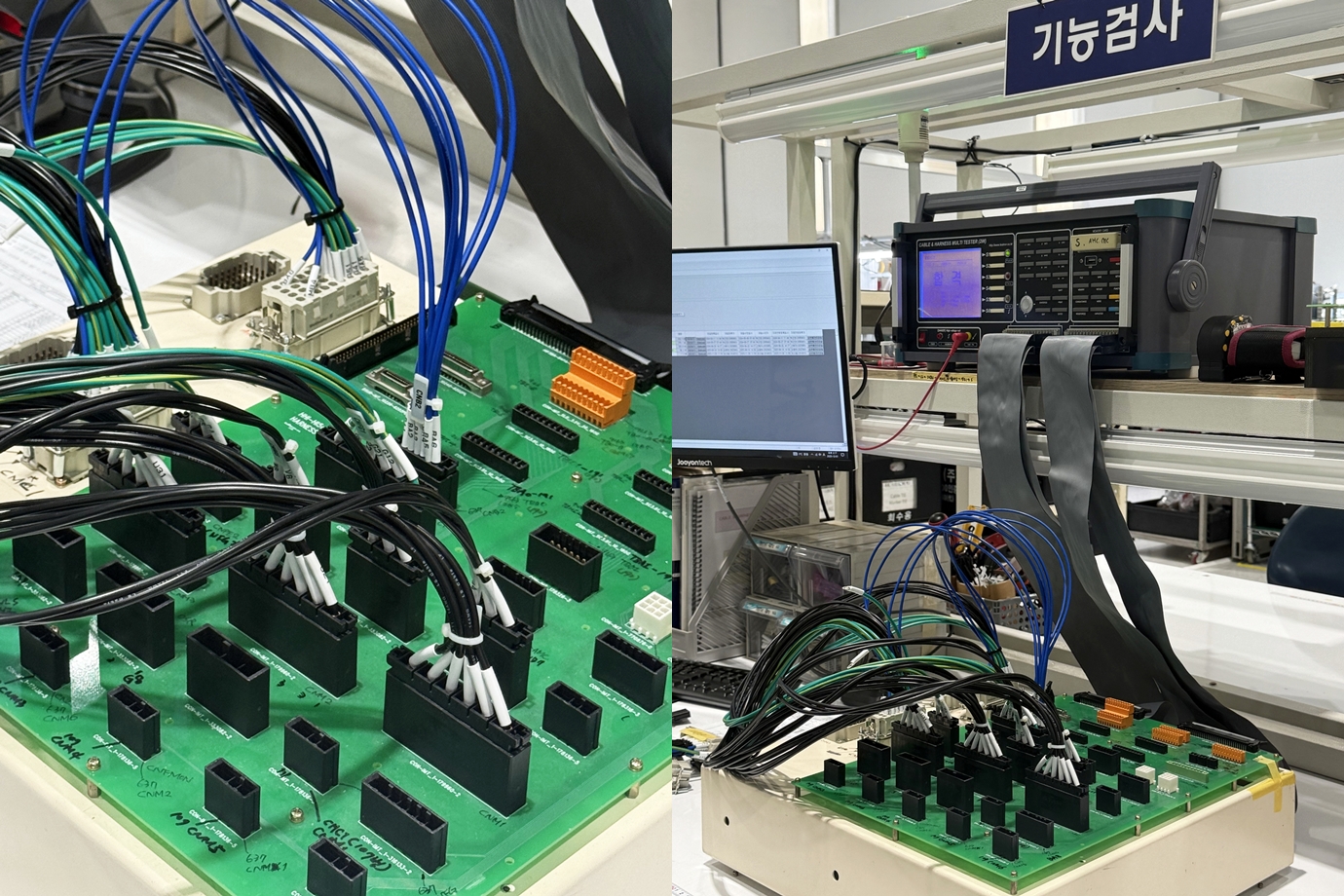

4) Testing & Inspection Equipment

Equipment that checks the electrical quality and connectivity of the assembled harness product. It conducts electrical inspections such as continuity and insulation resistance tests, and can quickly determine errors, short circuits, and open circuits. It can inspect dozens to thousands of pins simultaneously and can manage the quality history by storing the inspection results in a log. The test equipment can be seen as an essential process or equipment to detect defects in the product during the quality assurance phase.

Of course, the performance of many process equipment is important because it directly affects productivity and quality, but from the experience of BK Electronics, which has been making harnesses for a long time in the field, it cannot be denied that the real competitiveness starts at the design stage rather than the equipment itself.

A cable harness is not just a part that connects wires

Limited space, complex wiring paths, electrical reliability, durability, assemblability and cost are all examples of outcomes that need to be considered simultaneously. Most of the answers that meet all of these requirements are before drawing or in the early stages of design. The success or failure of a project is determined by how much understanding and fresh ideas you can offer to your customers.

BK Electronics’ approximately 40 years of experience with cable harnesses go beyond simple work skills. Through numerous instances of industrial equipment, electronics, and specialized cable harnesses, we have learned that there is more than one way to approach and solve even the same requirements. Changing the wire specification simplifies the assembly process, and significantly reduces defect rates and work time with a small adjustment of the connector position. This decision can only be made after numerous failures and improvements.

If you are looking for a true partner in a cable harness, please contact BK Electronics.

BK Electronics’ approximately 40 years of experience with cable harnesses go beyond simple work skills. Through numerous instances of industrial equipment, electronics, and specialized cable harnesses, we have learned that there is more than one way to approach and solve even the same requirements. Changing the wire specification simplifies the assembly process, and significantly reduces defect rates and work time with a small adjustment of the connector position. This decision can only be made after numerous failures and improvements.

If you are looking for a true partner in a cable harness, please contact BK Electronics.