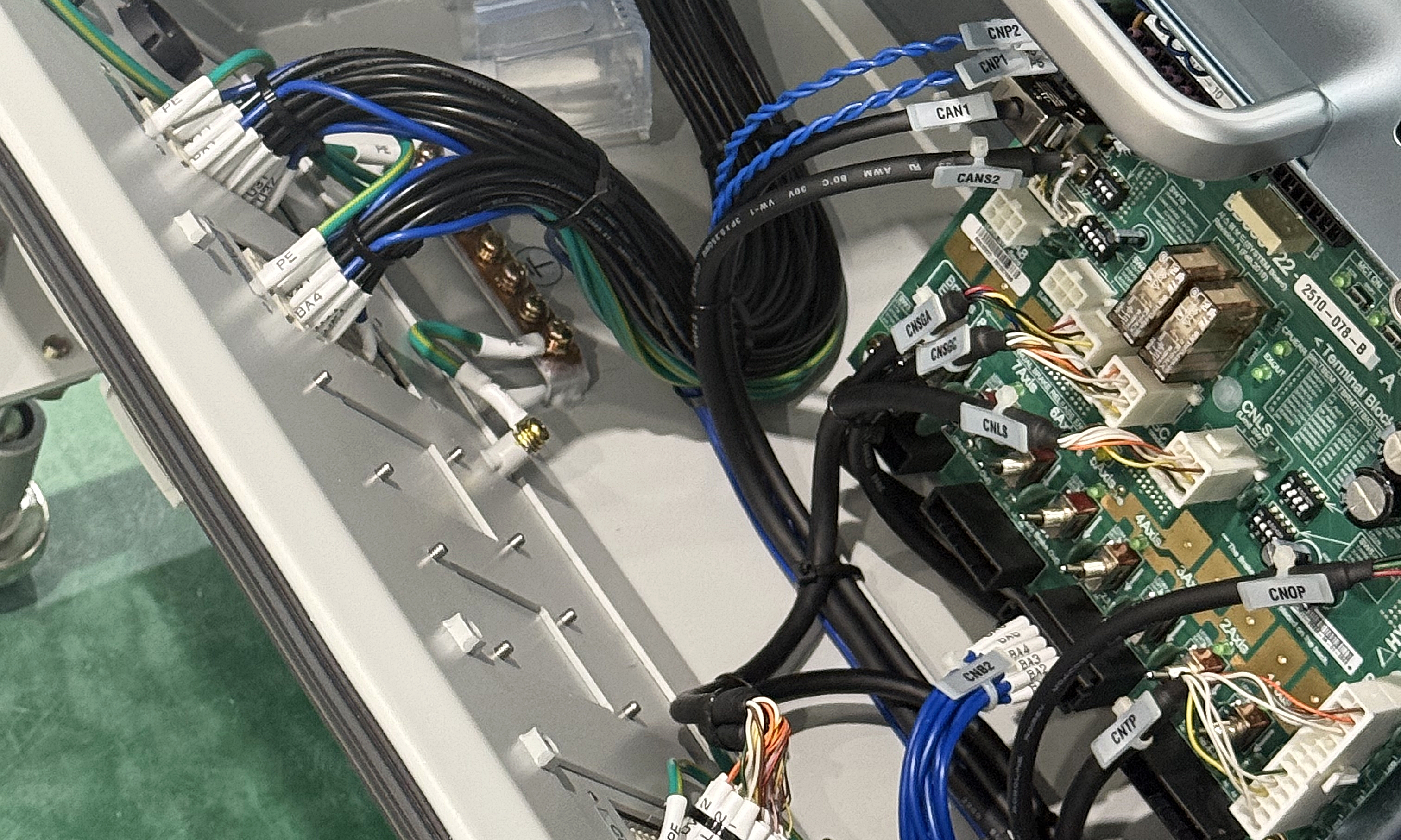

Key components that determine stability and reliability, wire harnesses🪢

Electric signals and power are exchanged in every car, smartphone, and home appliance that we use every day. Wire harnesses are the core component that connects this flow stably and is invisible. It can be said to be an industrial neural network that binds the complex wires inside the machine to give order and breathe life. Just as not all nerves are the same, the types of harnesses required vary widely depending on the purpose and environment of the product. Beyond simple wire bundles, let’s look at the types and characteristics of various wire harnesses optimized for each purpose.

“What are the types of harnesses?”

🟠 Medical Device Harness

➡️ Medical harnesses, which require high insulation and safety because they are used for equipment in direct contact with patients, must be able to handle sensitive biosignals and must be produced repeatedly through sterilization and disinfection processes. They must also be durable and reliable because the equipment must be used continuously for an extended period of time. Because medical device connectors must be very stable once fixed, locking and waterproof structures are often applied to prevent unnecessary deletion.

Therefore, medical harnesses can be viewed as special purpose harnesses that are more sophisticated and built to a higher standard than regular harnesses.

🟠 Robotics Harness

➡️ Unlike regular industrial harnesses, robot harnesses designed to withstand constant movement, high speed motion, and repetitive bending are optimized for dynamic environments such as robot joints, rotation, and sliding, so flexibility, strength, and electrical stability are critical. The requirements vary slightly depending on the type of robot. It can be summarized as below.

🦾 Industrial robots (welding, assembly, handling) → Heat resistance, flexibility, high strength

🦾 a cooperative robot → Flexibility, Lightweight

🦾 a medical robot → low-noise, high-precision

🦾 Service robot → Small and lightweight

In other words, robots can be seen as an optimized high-tech Haes.

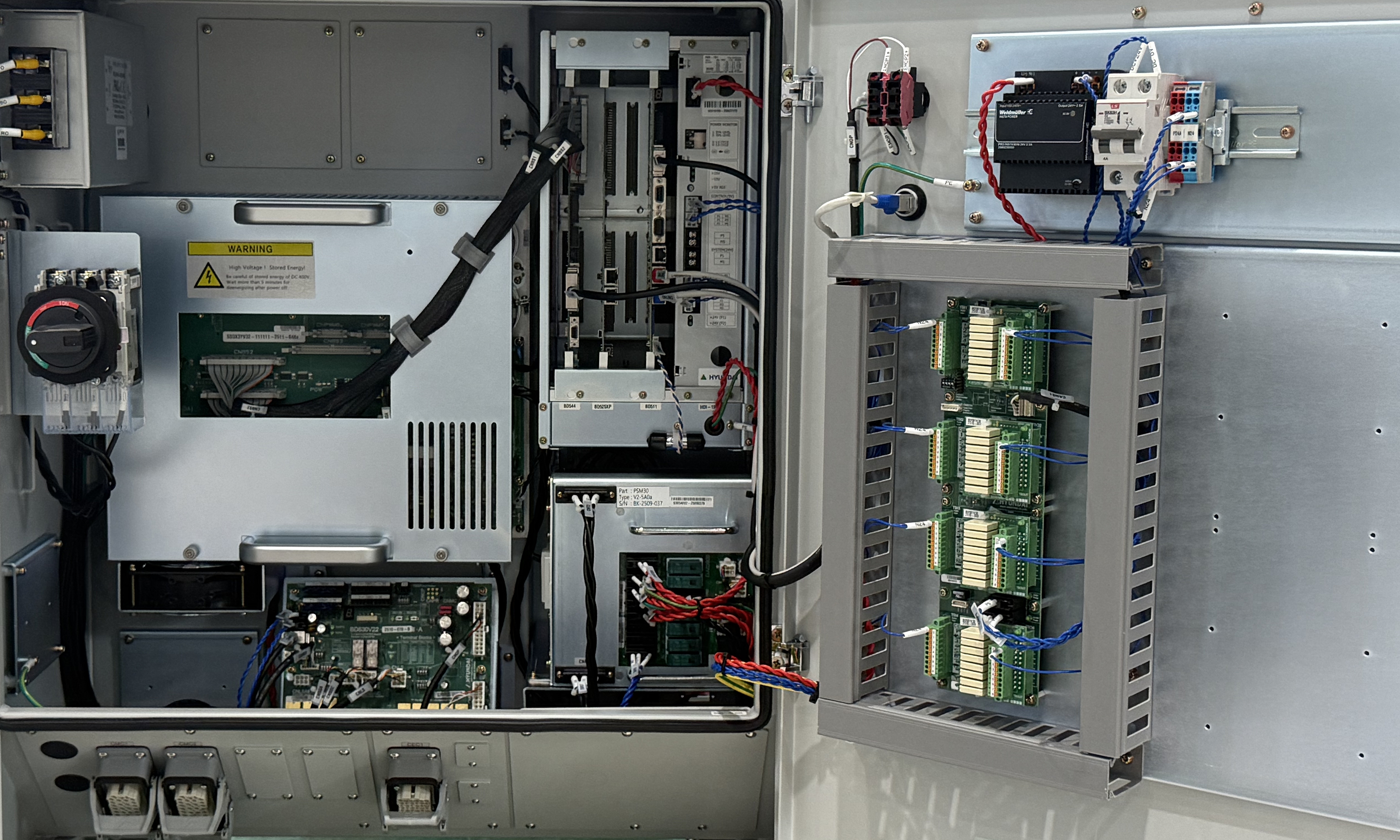

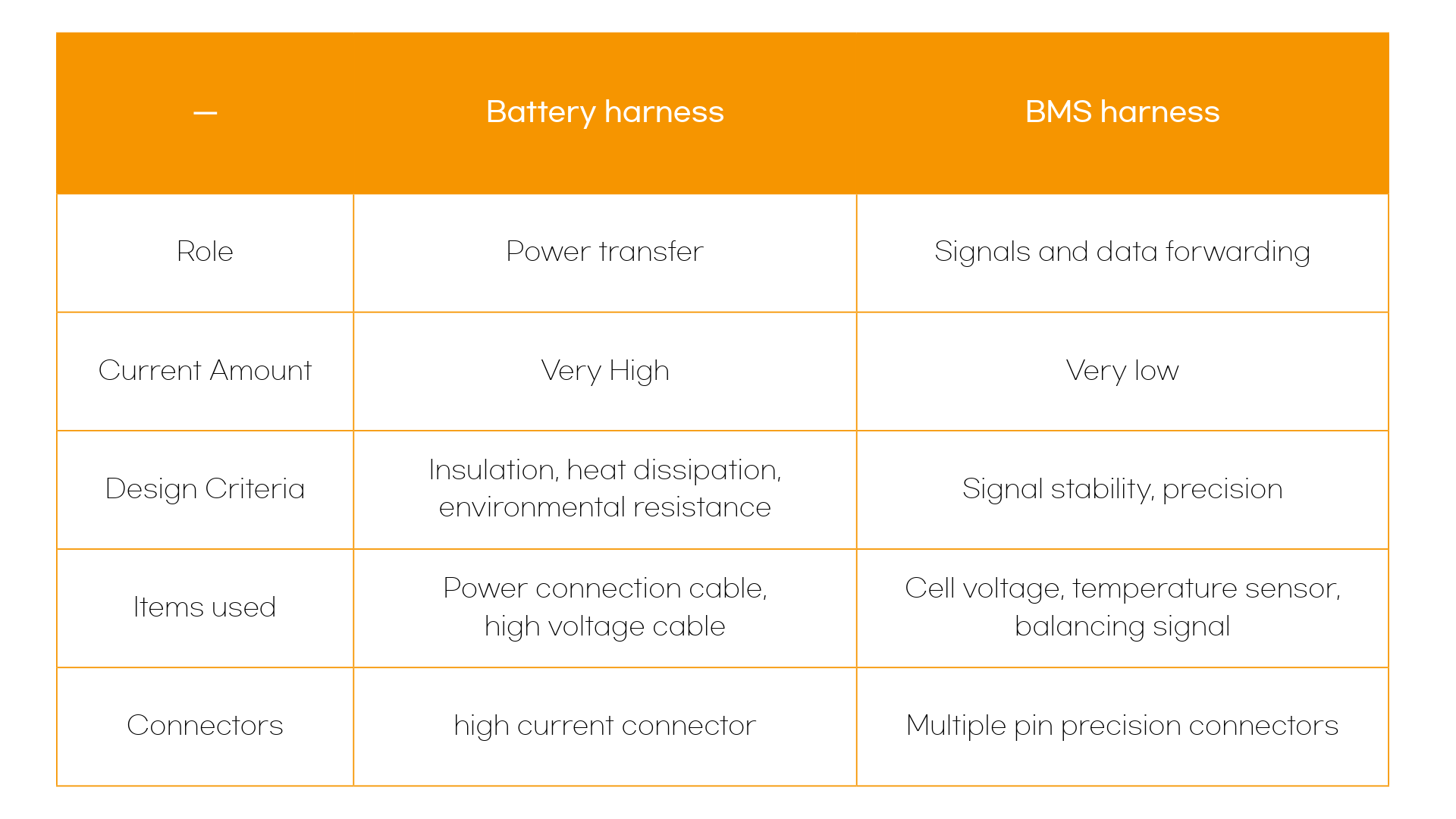

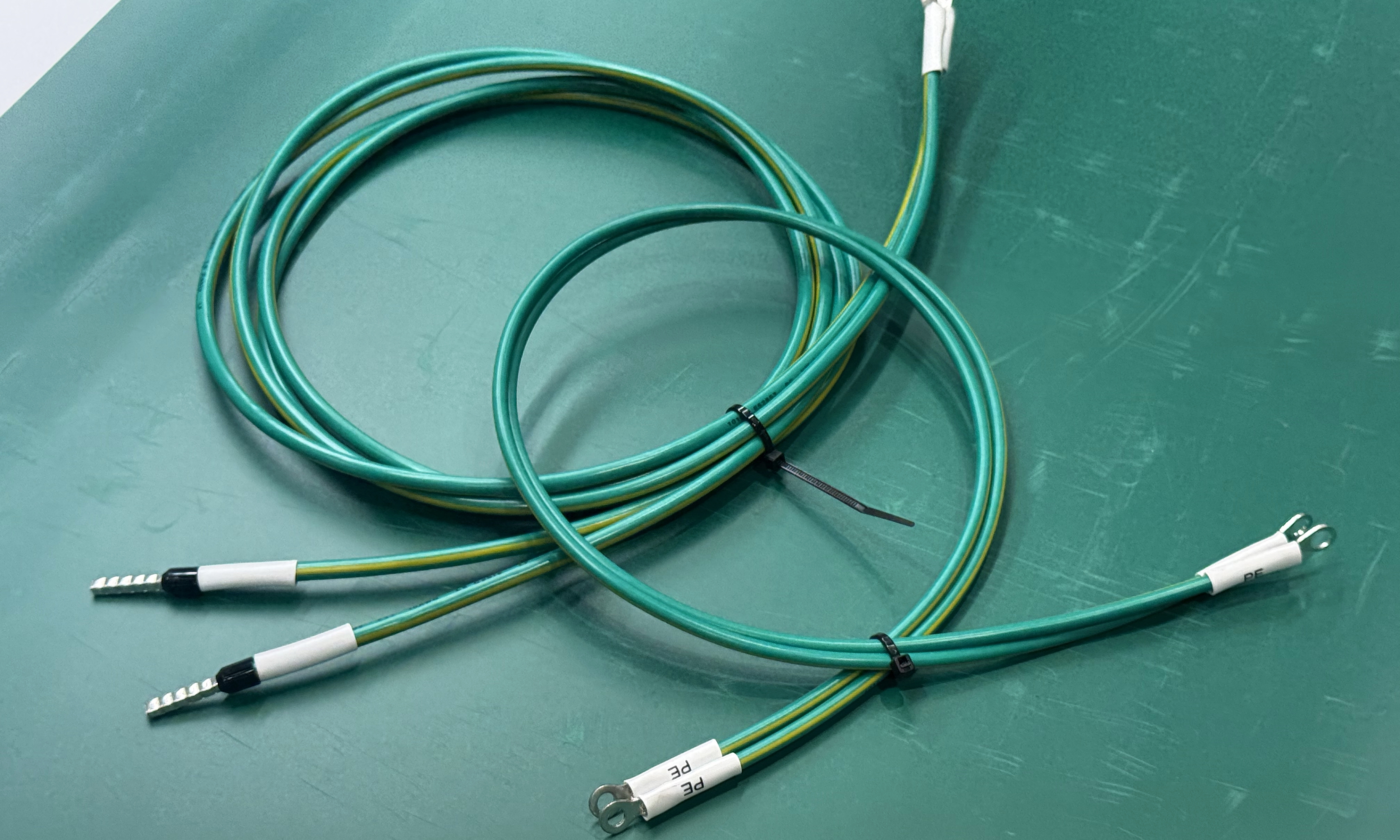

🟠 Battery & BMS Harness

➡️ Battery harnesses have strong power and an environmental-resistant design. Similar but slightly different BMS harnesses measure the condition of battery cells and transmit them to BMS circuits, which are key features of accurate signal transmission, insulation stability, and EMI suppression.

🟠 RF & High-Frequency Harness

➡️ It refers to a harness for ultra-precise communication that is completely different in design from ordinary power harnesses and signal harnesses. It consists of cables and connector parts to accurately deliver wireless signals or high-speed data signals. Since it handles high-frequency signals, subtle structural differences can have a significant impact on performance. Therefore, strong shielding performance and maintenance of impedance matching are essential requirements.

🟠 Waterproof Harness

➡️ Special harnesses that must maintain electrical stability even in environments where water, moisture, dust and chemicals penetrate require a much higher level of protection and environmental resistance than regular harnesses. Meeting the water/dust resistance rating is standard, and the wires and connectors are completely sealed to prevent water from accumulating or spattering liquids from penetrating into the wire contacts. Waterproof harnesses can be seen as environmental harnesses that must not only be waterproof but also robust to the entire external environment

🟠 Power & High-Current Harness

➡️ Designed to reliably supply tens of amps to hundreds of amps or more, the harness features a thick conductor and excellent insulation performance. In addition, heat management is critical because large currents can generate heat from lines and connectors, which can lead to fires. High current harnesses must be able to withstand both heat and vibration environments to reliably transmit high power.

🟠 Military Harness

➡️ It is an ultra-reliable harness used in military vehicles, fighter jets, communications equipment, and missiles and complies with the Military Standard (MIL-SPEC). It must be able to cope with extreme temperatures and must be registered as an International Arms Regulation (ITAR).

”Why Companies Making Military Harnesses Need ITAR Registration❓”

– Radar, aircraft, military vehicles, tactical equipment

– For connection to special electronic systems

– High-trust harness applied to missiles and weapon systems

– Items that have obtained by military standards

In addition to these features, design drawings and specifications can also be classified as military technology, so ITAR regulations must be followed.

🟠 Aerospace Harness

➡️ It is a special harness that requires ultra-high reliability, weight reduction, and environmental resistance because it is an electrical signal connection part used in extreme environments such as aircraft, helicopters, drones, satellites, and rockets.

Aerospace harnesses must be safe and reliable in extreme conditions, making them the best harnesses, including lightweight design, strong shielding performance, and the use of MIL-SPEC-based aviation-specific connectors.

🟠 Military Harness

➡️ It is an ultra-reliable harness used in military vehicles, fighter jets, communications equipment, and missiles and complies with the Military Standard (MIL-SPEC). It must be able to cope with extreme temperatures and must be registered as an International Arms Regulation (ITAR).

”Why Companies Making Military Harnesses Need ITAR Registration❓”

– Radar, aircraft, military vehicles, tactical equipment

– For connection to special electronic systems

– High-trust harness applied to missiles and weapon systems

– Items that have obtained by military standards

In addition to these features, design drawings and specifications can also be classified as military technology, so ITAR regulations must be followed.

🟠 Aerospace Harness

➡️ It is a special harness that requires ultra-high reliability, weight reduction, and environmental resistance because it is an electrical signal connection part used in extreme environments such as aircraft, helicopters, drones, satellites, and rockets.

Aerospace harnesses must be safe and reliable in extreme conditions, making them the best harnesses, including lightweight design, strong shielding performance, and the use of MIL-SPEC-based aviation-specific connectors.

In the past, it was simply a “bundle of wires.”

Wire harnesses of the future are evolving into a “highway” that carries data and a “smart grid” that manages energy. The smarter the machine becomes, the bigger the role of wire harnesses, the neural networks that connect the inside, will play. Please watch the progress of wire harnesses and BK Electronics, which do their part in the deepest part of technological innovation, although it is not visible.

🔦If you are wondering which harness is suitable for your project, please contact BK Electronics now!