“Is finding cheaper wires the answer?”

Wiring harnesses serve as the “nervous system” of modern industrial products, particularly in the automotive and consumer electronics sectors. However, because they consist of thousands of intertwined wires, connectors, and terminals, their inherent complexity leads to a high cost ratio and makes them notoriously difficult to manage.

True cost reduction in wiring harnesses is not just about finding cheaper raw materials. The core lies in how strategically you optimize the Bill of Materials (BOM)—the most critical blueprint of the product.

📌 We will explore optimization strategies for the BOM structure to reduce the cost of wiring harnesses.

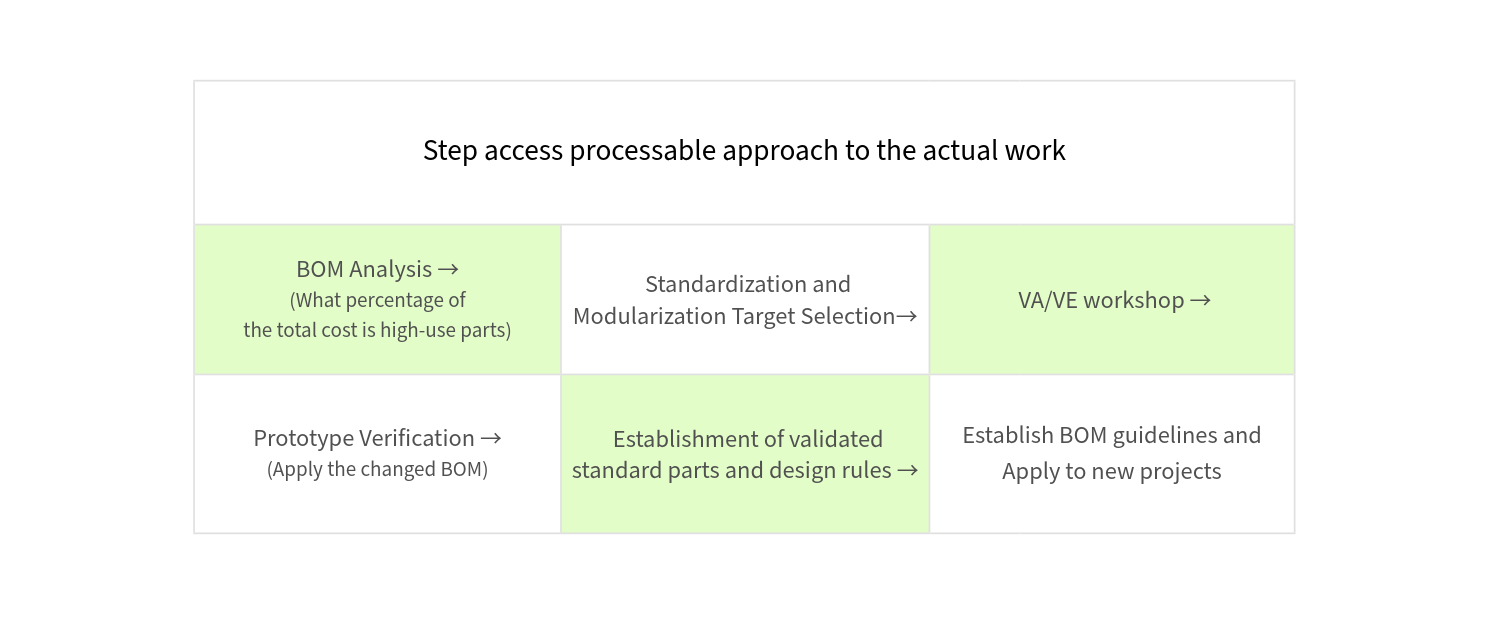

1.Standardization and Commonality: Preventing BOM Fragmentation

2.Modular Design: Creating a Structure to Overcome Complexity

3.Specification Optimization through VA/VE

4.Digital Twin and BOM Integrity

5.Restructuring the BOM Considering the Supply Chain

🟨 Standardization and Commonality to Prevent BOM Fragmentation

The very first strategy to prioritize is component standardization. A single finished product or complex piece of machinery contains numerous wiring harnesses. If unique connectors, terminals, and wires are used for each application, the number of line items in the BOM grows exponentially. This inevitably leads to diminished purchasing leverage and rising management costs. To prevent this cost escalation, you can significantly lower unit costs by consolidating connectors that perform similar functions and concentrating your purchasing volume. Furthermore, standardizing wire specifications—such as color, gauge, and insulation material—to a minimum set of varieties reduces the frequency of changeovers on the production line, thereby maximizing process efficiency.

→ Integration of connectors and terminals + Simplification of wire specifications

🟨 Modularization

In the past, it was common practice to design a single, massive wiring harness as one whole piece. However, this approach forces the creation of a separate BOM for even minor option differences, resulting in an administrative nightmare. The solution to this is BOM Modularization.

① Restructure the harness by decoupling it into functional units—such as the engine room, dashboard, and doors—and connecting them through standardized interfaces.

② Adopt a system where additional modules are added to a base harness according to specific options. → This eliminates the need to maintain hundreds of derivative BOMs.

(This enables a flexible response through the combination of a small number of standard modules, which minimizes costs incurred by engineering changes.)

🟨 Value Analysis/Value Engineering

Value Engineering (VE) is the pinnacle of BOM structure optimization. You must constantly question whether the components currently listed in the BOM truly require their specified level of performance. This involves redesigning to optimal specifications—for instance, verifying if expensive high-heat resistant wires are being used in sections where they aren’t necessary, or if the wire gauge is over-engineered relative to the current density. Furthermore, if the price of certain materials skyrockets, you should consider alternative materials that remain within the range of permissible electrical characteristics.

🟨 Digital Twin and BOM Integrity

There is another often-overlooked cost reduction opportunity: narrowing the gap between the Engineering BOM (E-BOM) and the Manufacturing BOM (M-BOM). Since 3D routing is critical for wiring harnesses, leveraging digital design tools to optimize the actual required wire lengths down to the millimeter can significantly minimize material waste. Keep in mind that when scaling up to mass production—tens of thousands of units—these minor millimeter-level adjustments translate into massive cumulative cost savings.

🟨Restructuring the BOM for Supply Chain Resilience

Due to the labor-intensive nature of wiring harness assembly, it is advantageous to simplify the BOM structure to facilitate production in regions with lower labor costs. While using global common parts is beneficial, it is equally important to manage both risk and cost by multi-registering alternative components in the BOM that can be sourced locally. This approach takes into account logistical expenses and customs duties, allowing for a more flexible and cost-effective supply chain.

“The degree of BOM standardization and the elimination of over-specifications are the ultimate factors that determine the competitiveness of the wiring harness business.”

Cost reduction in wiring harnesses is the process of refining structural complexity into a manageable form. True cost competitiveness is only secured when the standardization of components, modularization of structures, and continuous validation through Value Engineering work together in organic synergy.