│ The entire modern industry is entering the era of high voltage and high current.

From energy storage systems, high-power industrial robots, and smart grids, high-voltage harnesses have evolved beyond mere bundles of wires to a key infrastructure that determines the system’s survival. With the introduction of an 800V ultra-high-voltage charging system, the design paradigm of cable harnesses is now being reshaped around three pillars: thermal management, insulation, and absolute safety.

🔶 heat to determine the specifications of a high voltage harness

The higher the performance of an electronic device, the more current the cable has to handle. Physical laws produce heat when current flows, which goes beyond just heating up parts, and leads to a system-wide degradation in efficiency and fire risk. High Voltage Harness Thermal management is the most challenging task in cable harness design. The key to thermal management lies in minimizing resistance (R) and optimizing the heat dissipation structure. Therefore, the amount of heat generated by a conductor follows Joule’s law below.

The higher the performance of an electronic device, the more current the cable has to handle. Physical laws produce heat when current flows, which goes beyond just heating up parts, and leads to a system-wide degradation in efficiency and fire risk. High Voltage Harness Thermal management is the most challenging task in cable harness design. The key to thermal management lies in minimizing resistance (R) and optimizing the heat dissipation structure. Therefore, the amount of heat generated by a conductor follows Joule’s law below.

In the above-mentioned law, I stands for current, so even a small increase in current causes the amount of heat (Q) to increase rapidly in square proportion. To solve this problem, modern harnesses need to focus on balancing lightweight and heat dissipation performance by using highly heat-resistant coating agents or introducing aluminum conductors, not just making them thicker.

🔶 Isolation to determine the specifications of high voltage harnesses

In a low-voltage environment, insulation was at the level of a cover that prevented electricity from leaking out. However, insulation in the high-voltage era, where hundreds or thousands of volts flow, requires a different level of technology. When the voltage rises, electricity tries to penetrate the insulator and jump into the air. This is called an arc phenomenon. The dielectric strength of the material must be maintained for perfect insulation. The key is to design the insulation layer not to collapse even slightly in harsh environments such as external moisture, temperature changes, chemical corrosion, etc. Now, rather than a simple interpretation of “trapping electricity,” special materials such as crosslinked polyethylene or silicone rubber should be adopted to maintain insulation performance without causing microscopic cracks.

In a low-voltage environment, insulation was at the level of a cover that prevented electricity from leaking out. However, insulation in the high-voltage era, where hundreds or thousands of volts flow, requires a different level of technology. When the voltage rises, electricity tries to penetrate the insulator and jump into the air. This is called an arc phenomenon. The dielectric strength of the material must be maintained for perfect insulation. The key is to design the insulation layer not to collapse even slightly in harsh environments such as external moisture, temperature changes, chemical corrosion, etc. Now, rather than a simple interpretation of “trapping electricity,” special materials such as crosslinked polyethylene or silicone rubber should be adopted to maintain insulation performance without causing microscopic cracks.

🔶 Safety in determining the specifications of a high voltage harness

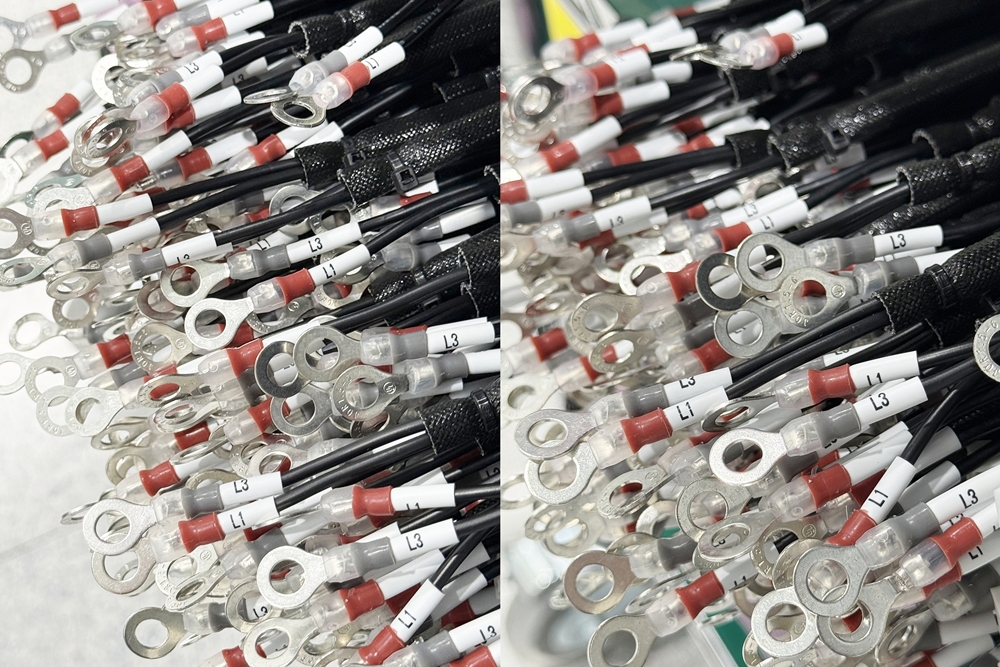

A strong electromagnetic field is created around the cable that conducts high voltage. This electromagnetic field is the primary source of electromagnetic interference (EMI) that distorts the signals of nearby precision instruments or causes malfunctions. Therefore, safety in high voltage harnesses is directly linked to “shielding” technology. To prevent electromagnetic energy inside the cable harness from leaking out, it is essential to wrap it with a braided layer or foil made of copper or aluminum. In addition, physical interworking with a circuit protection system that immediately cuts off power in the event of a physical impact or disconnection is the last safety device for the high voltage system to coexist with humans.

A strong electromagnetic field is created around the cable that conducts high voltage. This electromagnetic field is the primary source of electromagnetic interference (EMI) that distorts the signals of nearby precision instruments or causes malfunctions. Therefore, safety in high voltage harnesses is directly linked to “shielding” technology. To prevent electromagnetic energy inside the cable harness from leaking out, it is essential to wrap it with a braided layer or foil made of copper or aluminum. In addition, physical interworking with a circuit protection system that immediately cuts off power in the event of a physical impact or disconnection is the last safety device for the high voltage system to coexist with humans.

│ Cable harnesses in the era of high voltage are not common consumables.

Harnesses are the result of advanced engineering that traps energy safely, regulates the heat generated, and blocks unnecessary interference with external environments. Controlling enormous amounts of energy flowing from the invisible, this technological reliability will be a solid foundation for supporting the future high-power industrial ecosystem. Heat, insulation, and safety become a key measure of a product’s performance and safety when three items are in harmony..